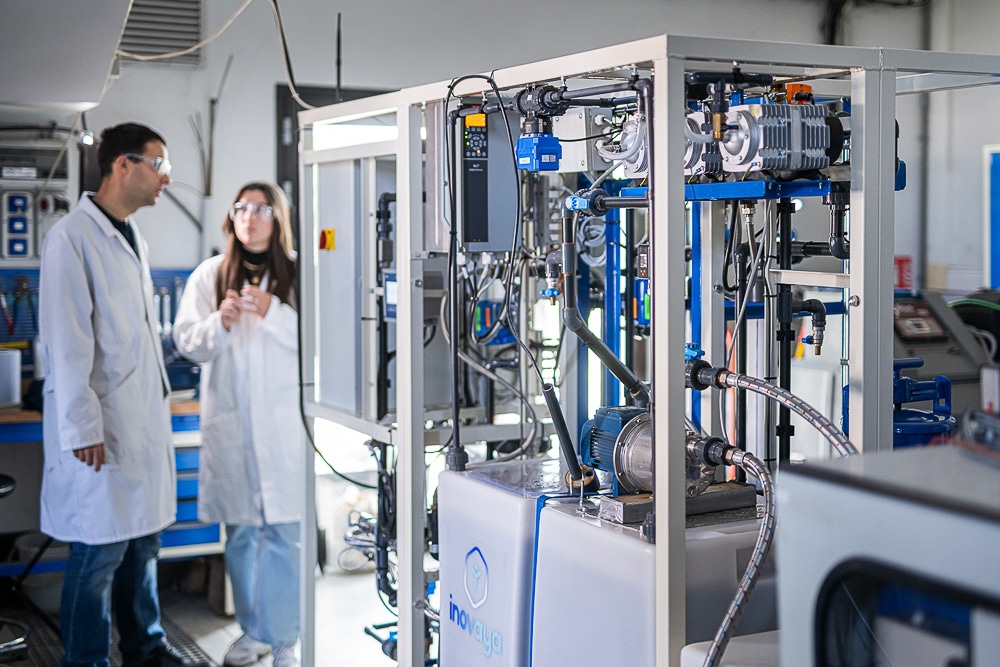

Our pilot units

An expert in water treatment and membrane filtration, InovaYa designs and manufactures tailor-made water treatment systems and pilot units in France to meet the specific needs of NGOs, local authorities, industry and construction professionals. With its innovative approach, InovaYa aims to enable decentralized, local water management by adapting its solutions to suit the source used and the desired use.

Contact usSolving a specific specific water problems with a proven, tailor-made treatment system

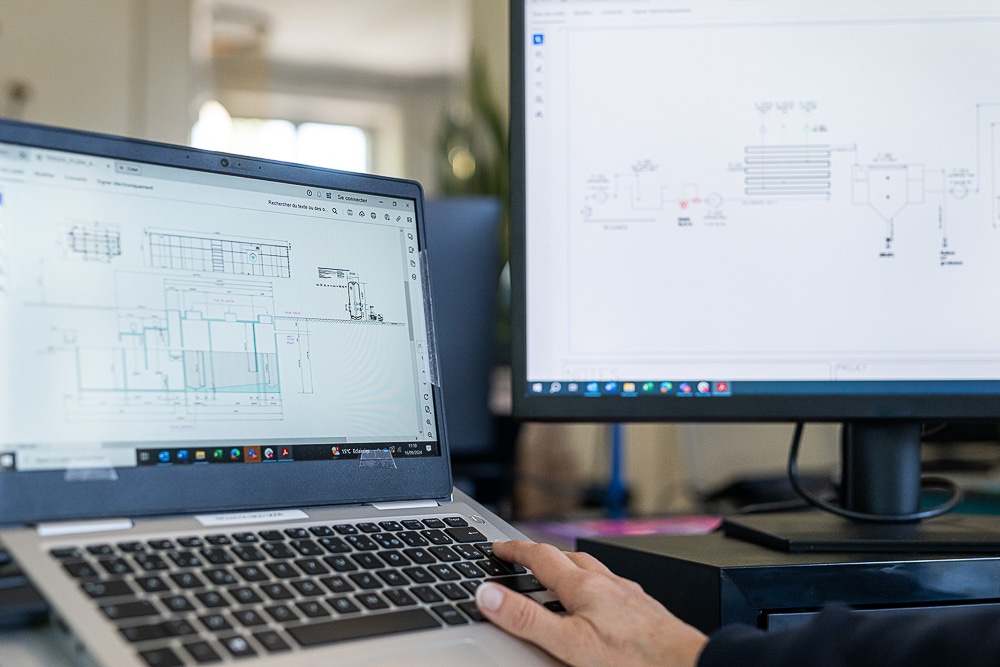

InovaYa's product catalog includes modular pilot units that can be used to test and validate the correct operation of a system directly on your premises, prior to future installation. These units can be made available to you for several weeks to several months, depending on your needs, the type of water to be treated and its output uses.

Innovation is an integral part of InovaYa's DNA, and we can develop innovative, tailor-made technological building blocks and new treatment units for problems that are not yet fully understood by our entire ecosystem.

For the treatment of water intended for human consumption (EDCH), the semi-standardized unYo®, aYa and recYf®units nevertheless meet the majority of needs worldwide.

Our complete offer made-to-measure

An expert in filtration and membrane water treatment, InovaYa has all the skills needed to support you throughout your projects, from water quality studies to system deployment in the field. NGOs, local authorities, industries, construction professionals, discover InovaYa's comprehensive, tailor-made offer.

Read moreOur inspiring projects

We work closely with our customers to bring high value-added projects to life, with the aim of making water management more responsible and access to the resource more evenly distributed.

All projectsQuestions frequently asked questions

The duration of the test can vary from several weeks to several months, depending on the specifics of your project, its constraints and the objectives to be achieved. During the audit phase, InovaYa's engineering department will provide you with a provisional schedule.

Tests carried out with a pilot unit can provide concrete proof of the proper operation and compliance of your water. For example, pilot tests are highly recommended when applying for prefectoral authorization (this is particularly the case for projects involving the reuse of water in industry and buildings).

Here are just a few examples of how a pilot unit can be set up: - Industrial water reuse - Potabilization of turbid river water - Treatment of specific pollution - Etc...

A pilot unit is used to test and validate a technology on a small scale before its deployment. Installed directly on your site, it enables you to simulate real-life operating conditions and optimize treatment parameters prior to industrial development. It is used when you have a specific water problem requiring a tailor-made treatment system to be tested beforehand. Once industrialized, it becomes a treatment unit. This is the term used to describe a unit designed to purify, filter or treat water to specific standards, of a certain quality for a certain use. A safety unit is a treatment unit that ensures that the water at the point of use is of good quality and safe to health, whether for drinking, hygiene or other essential needs. For example, it is particularly advisable to ensure water safety for fragile populations (infants, hospitalized people, the elderly, etc.) who are more vulnerable to water-borne infections and diseases. To ensure water safety, InovaYa has developed water safety units that treat network water degraded by continuous or occasional external contamination. These units act as a barrier against 99.9999% of bacteria and 99.99% of viruses, organic micropollutants (endocrine disruptors, pesticides, herbicides, drugs, etc.) and dissolved metals. For further information and personalized support, please contact our team by phone or fill in the form on our contact page to be contacted.